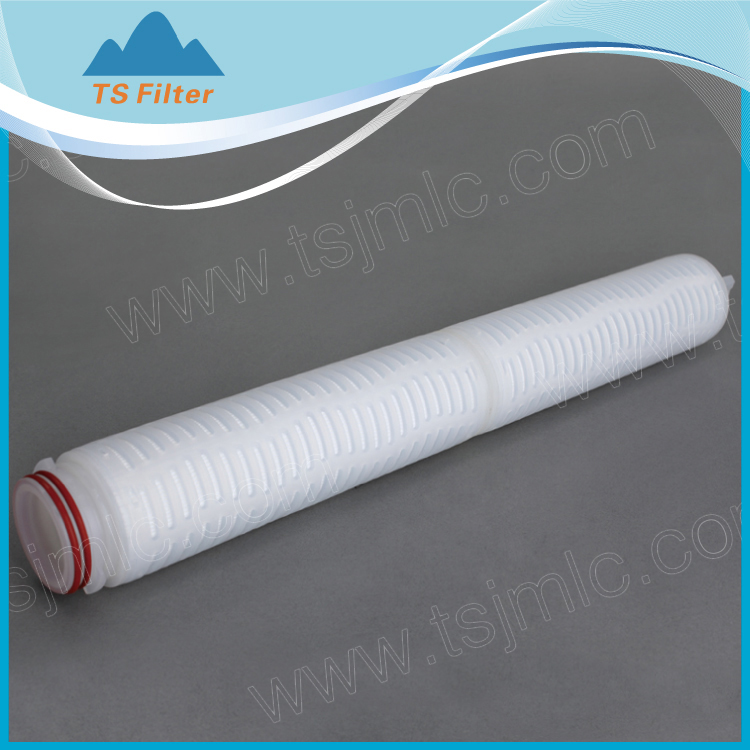

Factory made hot-sale PVDF Membrane 0.2 Micron Cartridge Filter for Fine Chemical Filtration

To be the stage of realizing dreams of our employees! To build a happier, extra united and extra professional team! To reach a mutual reward of our shoppers, suppliers, the society and ourselves for Factory made hot-sale PVDF Membrane 0.2 Micron Cartridge Filter for Fine Chemical Filtration, We welcome new and old shoppers to make contact with us by telephone or mail us inquiries by mail for foreseeable future company associations and attaining mutual achievements.

To be the stage of realizing dreams of our employees! To build a happier, extra united and extra professional team! To reach a mutual reward of our shoppers, suppliers, the society and ourselves for TS made Hydrophilic PVDF filter, We follow superior mechanism to process these products that ensure optimum durability and reliability of the items. We follow latest effective washing and straightening processes that allow for us to provide unmatched quality of products and solutions for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

◆Hydrophilic PVDF Membrane filter for liquids sterile filtration, Absolute rating ≥99.99%

◆Low protein binding and low extractables, ideal for bioburden reduction and particle removal

◆High throughput flow rate with minimal differential pressure

◆Broad chemical compatibility, suitable for aggressive liquids and high viscosity liquids

◆Withstand multiple steam sterilization

◆Replace Sartorius ,Pall or Millipore Filter is available

•Ophthalmics, WFl;

•Diagnostics, diluents, serum, tissue culture media and media additives;

•Sterile filtration of high viscosity liquid

•Strong alkaline, acids and corrosive solvents;

Table : Typical water flow rate (10″)

| Materials Of Construction | Filter Media: | Hydrophilic PVDF Membrane | ||||

| Support Layers: | Polypropylene | |||||

| Micron Rating: | 0.1, 0.2, 0.45, 0.65, 1.0, 3.0 um | |||||

| Inner core: | Reinforced Polypropylene | |||||

| Outer Cage, End caps: | Reinforced Polypropylene | |||||

| Seal Method: | Thermal Bonded, No Adhesives | |||||

| O-rings/gaskets: | Silicone, Nitrile, EPDM, Viton, Teflon, etc | |||||

| Cartridge Dimensions | Outer Diameter | 69mm(2.75”) | ||||

| Inner Diameter | 33mm(1.30”) | |||||

| Length(based on DOE end caps) | 10″- 254mm, 20″- 508mm, 30″-762 mm, 40″- 1016mm | |||||

| Filtration Area(m2) | 0.65 m2 per 10” | |||||

| Operating conditions | Normal Operating Temperature: | Up to 65℃ (140℉) | ||||

| Max.Operating Temperature.: | 90℃ (194℉) at △P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Normal Flow direction: | 4.2 bar (60 psi) at 25℃ (77℉) | |||||

| Reverse flow direction: | 2.1 bar (30psi) at 25℃ (77℉). | |||||

| PH Value compatibility: | 1-13 | |||||

| Sterilization: | Steam Sterilization for 30 minutes at 135℃(275℉) Cumulative Time: 50hours |

|||||

| Cartridge Safety | Endotoxin: | <0.25 EU/ml | ||||

| Extractables: | 0.03g / 10″ | |||||

| GRADE | PRODUCT | MICRON | ADAPTER | LENGTH | O-RING / GASKET | |

| F - FOOD & BEVERAGE | DHPV | 020-0.2um | AA- DOE | 10-10″ | S-silicone; N-nitrile | |

| P - PHARMACEUTICAL | 045-0.45um | CN-226/FIN | 20-20″ | E-epdm ; T-teflon (encaptulated) | ||

| C - CHEMICAL | 080-0.8um | BN-222/FIN | 30-30″ | V-viton | ||

| E - ELECTRICAL | 100-1.0um | BF-222/ FLAT SEAL | 40-40″ | How to Order?- Example | ||

| CF-226/FLAT SEAL | 05-5″ | Pharmaceutical grade; Micron:0.45um; Length:10″ ADAPTER: DOE; Gakset: Silicone. Selection Code is: PDHPV045AA10S | ||||

| EN-222 three locking ears /Fin | Other-XX | |||||

To be the stage of realizing dreams of our employees! To build a happier, extra united and extra professional team! To reach a mutual reward of our shoppers, suppliers, the society and ourselves for Factory made hot-sale PVDF Membrane 0.2 Micron Cartridge Filter for Fine Chemical Filtration, We welcome new and old shoppers to make contact with us by telephone or mail us inquiries by mail for foreseeable future company associations and attaining mutual achievements.

TS made Hydrophilic PVDF filter, We follow superior mechanism to process these products that ensure optimum durability and reliability of the items. We follow latest effective washing and straightening processes that allow for us to provide unmatched quality of products and solutions for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.